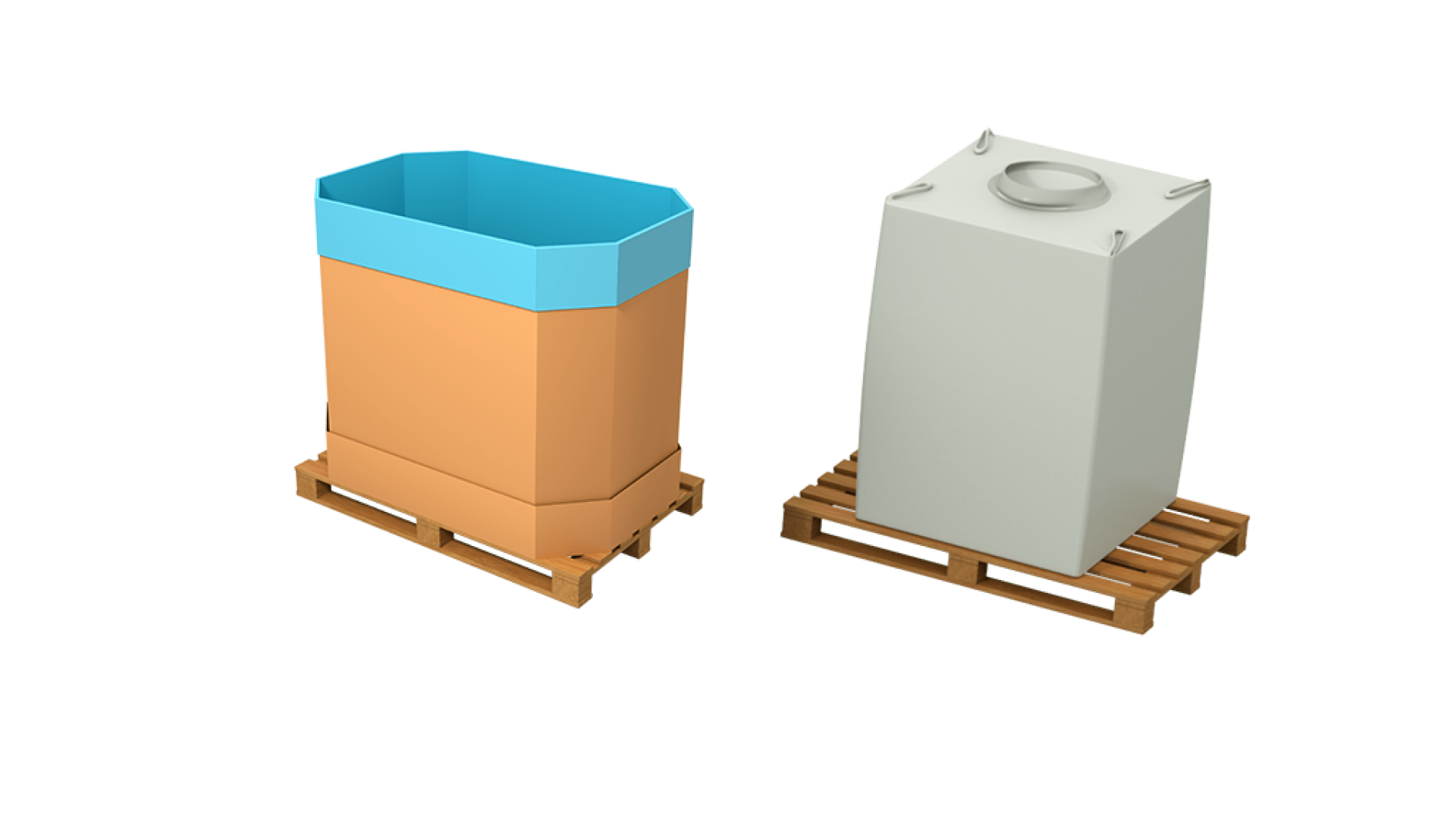

Big bag and octabin handling machines

Stand-alone FIBC & Octabin filling stations

Stand-alone bulk bag and gaylord filling stations designed for a typical output up to 12 packages per hour and this on a limited footprint.

Semi- automatic FIBC & Octabin filling lines

Tailor-made bulk bag and gaylord filling lines designed for a typical output varying between 15 to 50 packages per hour.

Mobile FIBC & Octabin filling systems

A broad range of mobile bulk bag and gaylord filling systems allowing you to fill your product on different locations within your plant and this in both indoor and outdoor conditions.

High care FIBC filling line

A big bag filling line designed to pack sensitive products like (infant) milk powder under clean room conditions with a focus on cleanliness and avoiding cross contamination.

Octabin & gaylord erecting systems

Reduce your labor costs by automating the intensive task of manual erecting of your octabins and gaylords.

FIBC handling and disinfection system

Remove your bigbags from a pallet and transfer them from your medium care into your high care processing zone via a UVC disinfection cell.

FIBC Unloading station

FIBC unloading stations with a modular design to empty your big bags in an efficient and dust-tight way into your downstream production process.