The best solution for your challenge

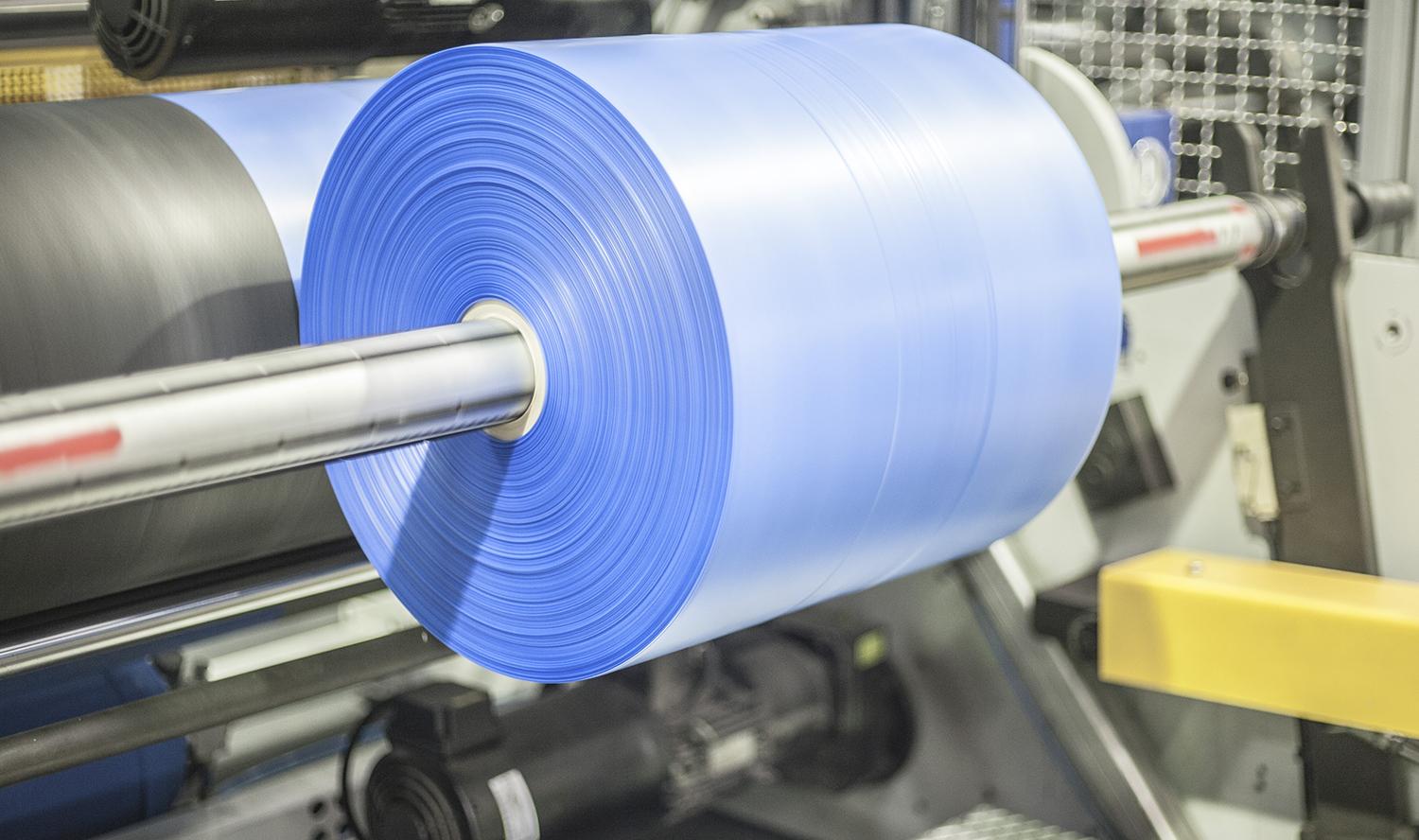

- 12 kg reels for continuous production thanks to the auto- matic film roll exchange.

- 60 kg reels for high autonomy.

- Big reels for the XL bag inserting machines.

- Use of made-to-measure bags or pre-made bags on the same bagmaker inserter

- Use of HDPE, MDPE, LDPE and special multilayer film adding different barriers

"Working with reels of PE film has the advantage that the machine automatically adapts the height of the bag to the box height. Additionally we reduced our bag cost by 30%.”

- Mr. César Fraga, Manager

SCL Coplacsil (Spain)

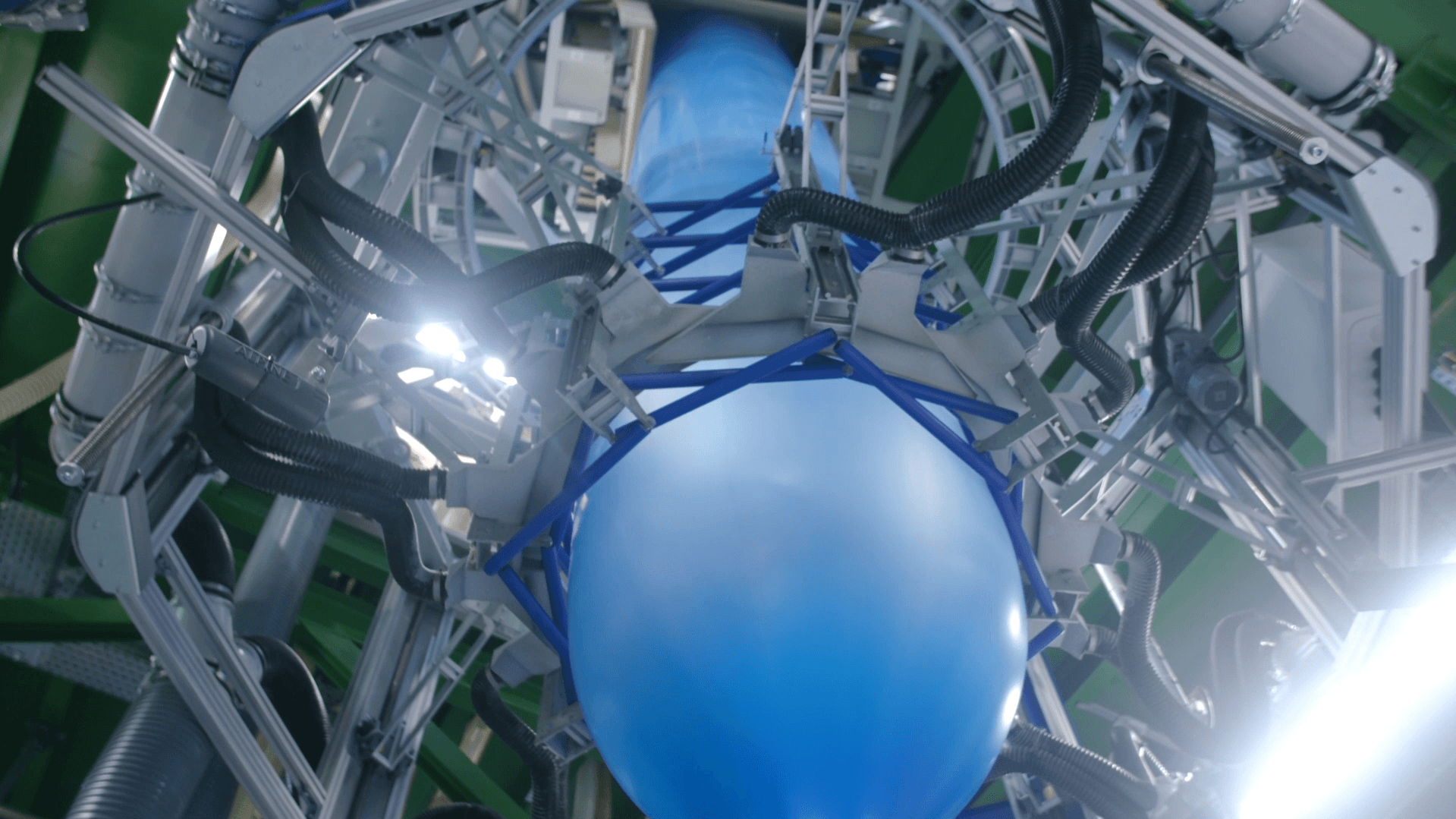

Expert advice on PE film

If you need advice about PE film you can count on the expertise of Pattyn. Take a look at the GMP - Pattyn Film Division website for more information.

Efficiency guarantee requirements: for each Pattyn bag inserter we provide you the film specifications that will guarantee an optimal performance.

Order the right film material and thickness: as raw material price is high and cost reduction is crucial, it’s very important to choose the right film material (LDPE, MDPE or HDPE) and the right film thickness for your application.

Make sure your film supplier:

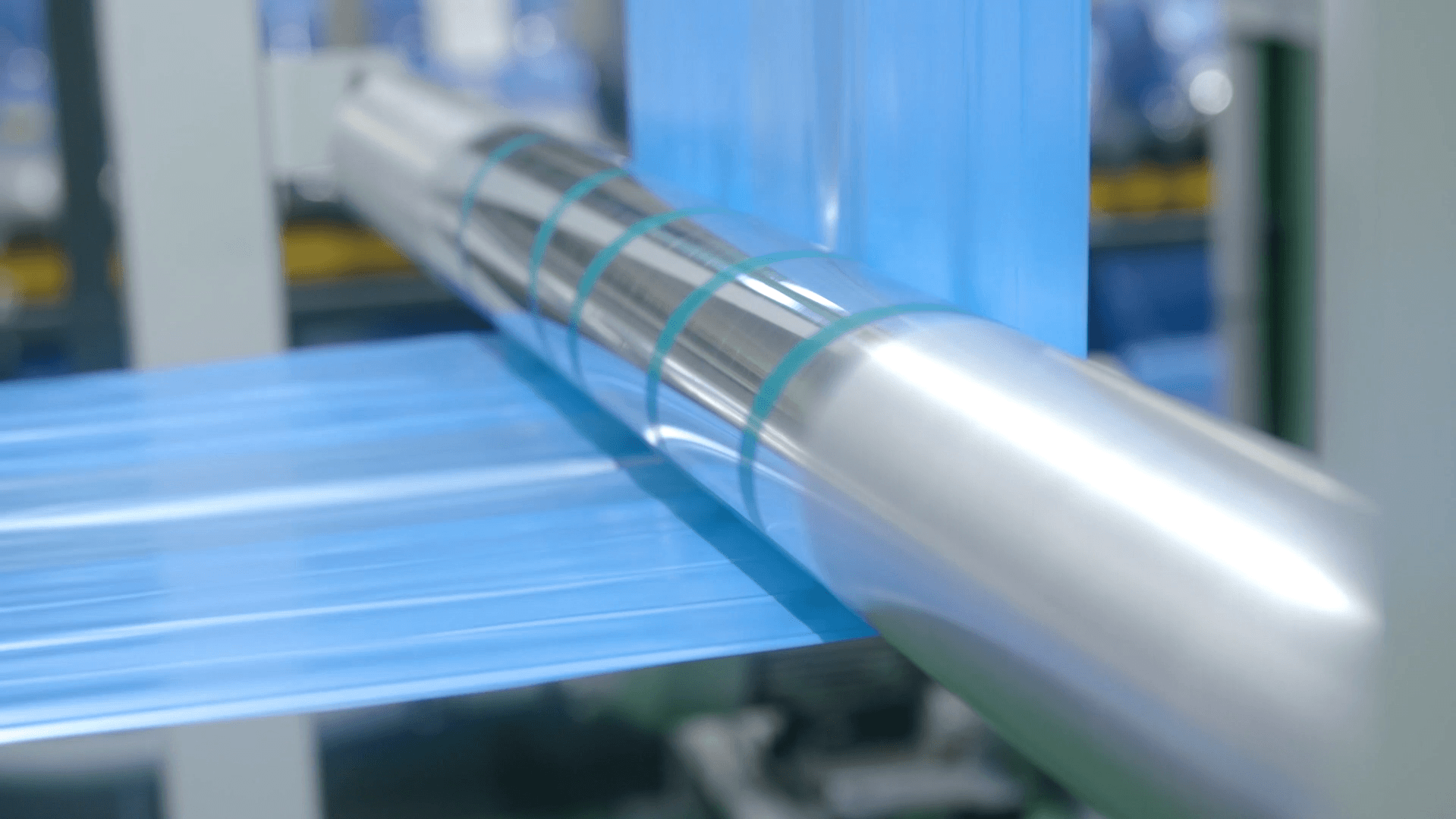

Checks the film tolerances and winding tension during extrusion, always delivers the same quality & meets the Food Grade Standards in case of food contact.

Download datasheet PE-film

Find out more about our PE film.