Optimize your frozen dough packaging

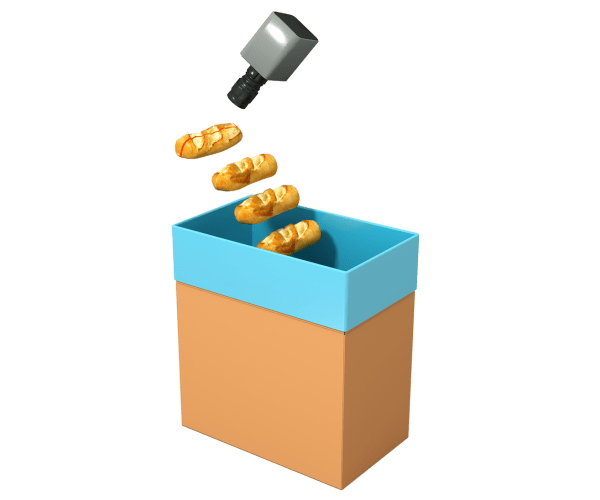

- Get precise counting at high speeds with our advanced vision system

- Ensure consistent quality by packing only products that meet exact customer specifications, with the most reliable rejection system.

- Achieve full product control with our integrated 3D vision, and even AI quality control solutions

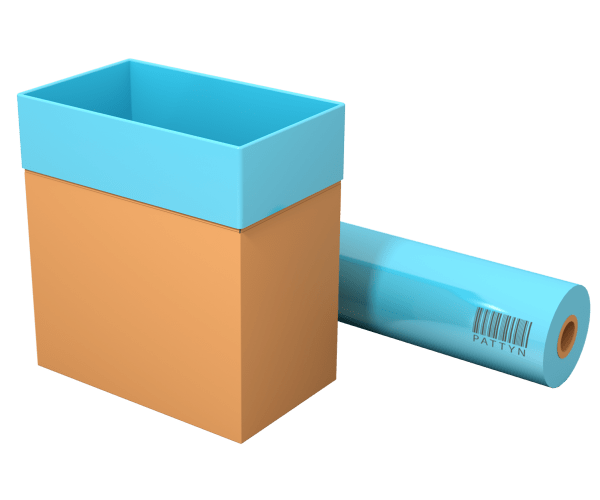

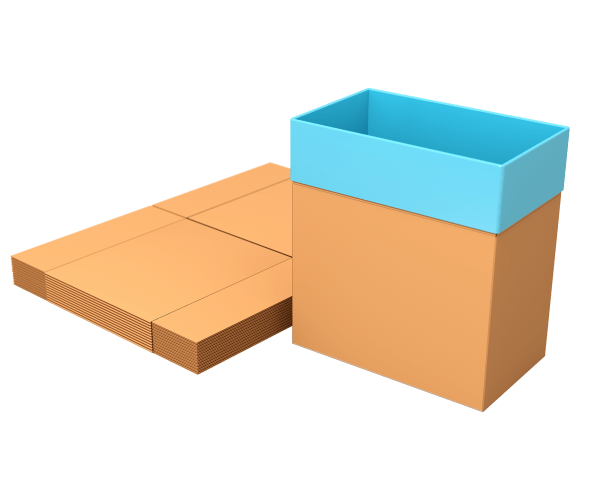

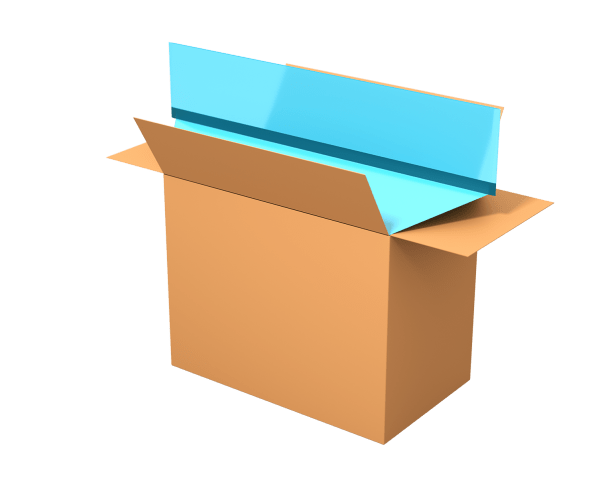

- Pack with flexibility and diversity - supporting a wide variety of packaging styles and products

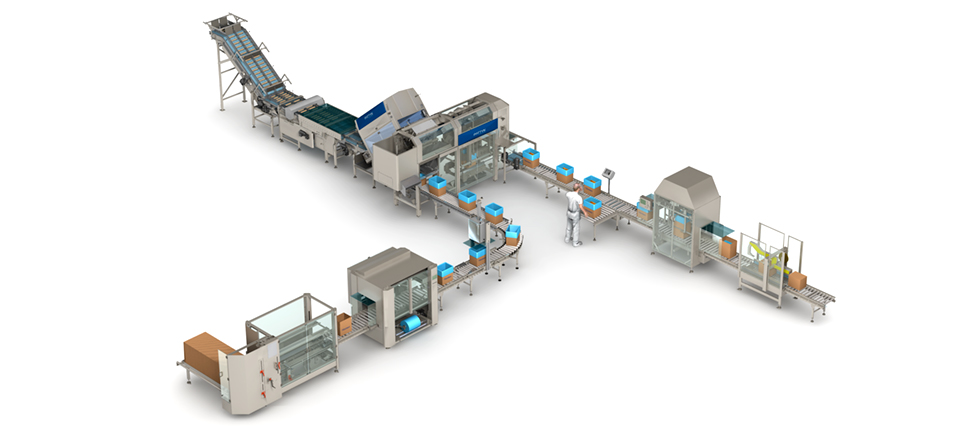

Watch our frozen dough line in action

See how a fully automated frozen dough line gives you a start to finish solution for all your packaging challenges.

Pattyn designs advanced packaging lines for all kinds of frozen dough products, perfectly aligned with your production goals. Frozen dough requires a specific packaging approach, which is why we've developed a range of solutions for various products. And if your product needs something different, we’re ready to customize the right solution.

Pattyn also integrates OEM equipment, taking full responsibility for the complete line and supports you before, during and after start-up of your project.

Origo

Looking to take the first step in automating your frozen dough packing process? Discover our Origo line - specifically designed for significant volumes that require automated packaging. Built more compactly while maintaining the same efficiency and quality.

Argo

Packing higher volumes and ready to take it up a notch? Get to know our Argo line - high-end, high volume solutions for the bakery industry, offering quality control, counting, and pick & place for large-scale production.

Download brochure

Discover more about our frozen dough packaging solutions in our brochure.