In this article, we zoom in on the cherry industry - a highly seasonal, global business driven by speed, precision, and flexibility. Across the world, every cherry grower faces the same race against time: massive volumes must be packed in just a few short weeks.

The pressure is real. Limited space, a shortage of skilled workers, and strict timing leave no room for error. That’s why more and more producers are turning to automated packing solutions to keep pace without compromising on quality or efficiency.

Cutting time and space with compact automation

Cherry season is unlike any other. Volumes explode in just a few weeks, yet packaging is still often done manually. This requires large teams of seasonal workers, who must be trained quickly and work under pressure.

Traditionally, cherries are packed in small crates that are pre-formed manually. Bags are often inserted into crates weeks in advance, consuming valuable floor space and labor hours.

And because cherries are shipped worldwide, sealing quality is crucial. Bags must remain intact during long-distance transport to guarantee freshness and avoid damage. Manual packaging processes place unsustainable demands on seasonal workers. The solution? Custom packaging solutions with smart automation.

Bag-in-box packaging system for every cherry producer

With time such a critical factor in the cherry sector, automation is the logical step forward. Modern packaging machines handle multiple box formats and crate types, cut labor needs, and allow for fast changeovers. There’s no need for pre-handling crates or bags - production can start exactly when the season does.

Automation delivers a higher throughput in less space, while compact food packaging machines can also be used off-season for other fruits. At the same time, growers benefit from reduced consumables, less stock, fewer errors, and consistent sealing quality - essential for global export.

From standalone bag-in-box machines to complete turnkey packaging line installations, Pattyn delivers the edge cherry producers need during the most critical weeks of the year.

Protecting cherries with precision bag inserting and sealing technology

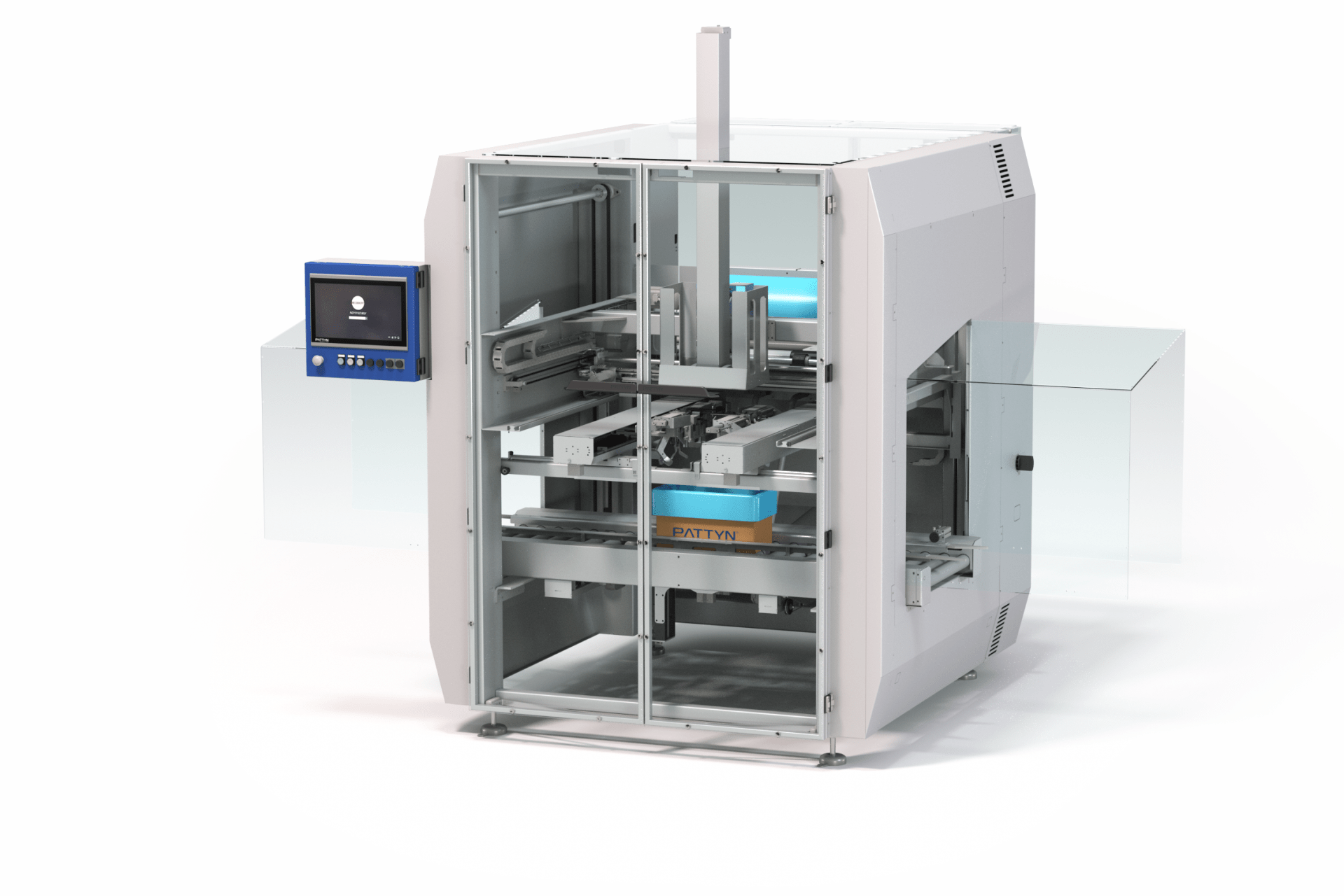

To ship cherries safely across the globe, high-quality packaging is non-negotiable. Beyond the benefits of speed and reduced manual labor, automation also guarantees packaging quality. That’s where the RAZIM-51 bag inserter and the DS-41 bag sealing machine step in.

The RAZIM-51 positions each bag perfectly inside the cherry crate, delivering the best bottom seal on the market.

After filling, the DS-41 takes over, automatically decuffing, stretching, and heat-sealing the bag. The result is a flawless seal - tight, reliable, and designed to protect delicate cherries throughout long-distance shipping.

With these robust packaging solutions, cherries are packed securely, efficiently, and without damage. Producers gain peace of mind, and buyers receive cherries in perfect condition.